Today to nozzle, Cedric Muller, the official reviewer of Nozzle.io is going to test PETG Silver from Aceaddity. Below is Cedric's detailed and comprehensive review of our PETG filament.

The brand :

Aceaddity is a young brand, I don't have the exact date but it seems to me that the creation of the company dates from this year. It is therefore a young, innovative company with the aim of bringing 3D printing to the wider world! (taken from their presentation:Aceaddity About Us).

For my part, I discovered Aceaditty following several competitions held on Facebook. Indeed, in one of them, I had the chance to win a prize, with the choice of resin or filament. so I chose filament, tricolor silk gold, copper and black to be exact!

Filament that I also used during my test of the Creality K1.

Every month, they develop their ranges a little more, and so I am going to test their PETG Silver.

Already the packaging is simple, without embellishment, a cardboard box with minimal printing. The spool is vacuum sealed and the bag has a zip, which makes it reusable. In addition, the reel is made of cardboard, which is more “ECO” than the plastic reels which end up piling up at the bottom of our garages… 😂

One thing I also like is the graduation on the side opening of the spool which allows you to know what is left.

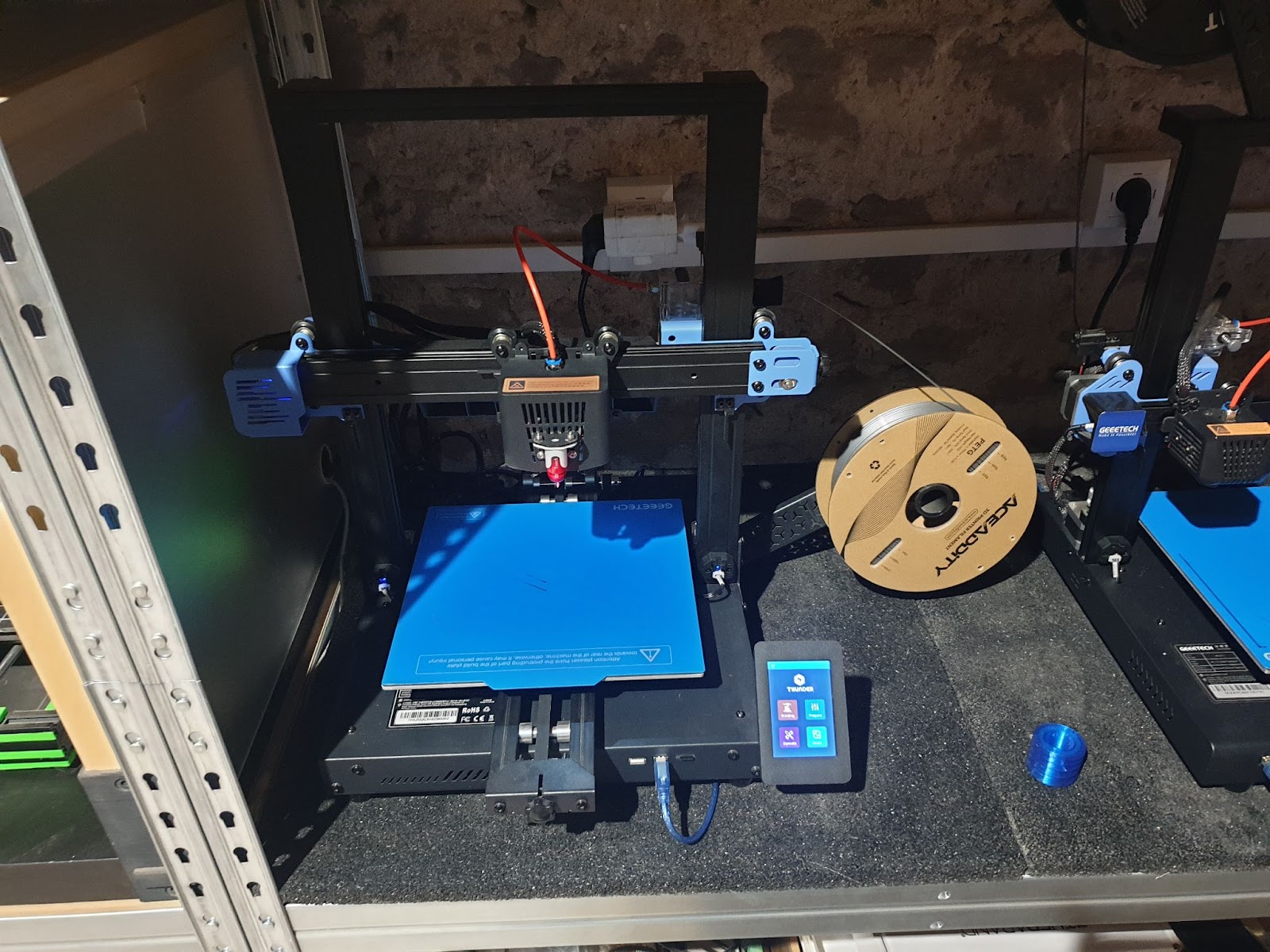

To test this filament, I will use my Geeetech thunder. In fact, my K1 being very busy at the moment, it has the highest speed just after. Speed I will need for non-printing move movements. As PETG has a strong tendency to drool, a high 'Travel' speed helps to partly avoid stringing.

For the slicer, I am still under prusaslicer and for the parameters here they are

- Nozzle temperature: 230°C for the 1st layer then 225 for the others.

- Heated bed temperature: 80°C for the 1st layer then 75 for the others.

- Printing speed, 50 mm/s, displacement 300mm/s (maximum depending on the distances due to the acceleration parameter of the machine).

- Retraction of 6mm (it's bowden) at 35mm/s with a z-hop of 0.2mm

- A wipe during retraction with 75% retraction before the wipe.

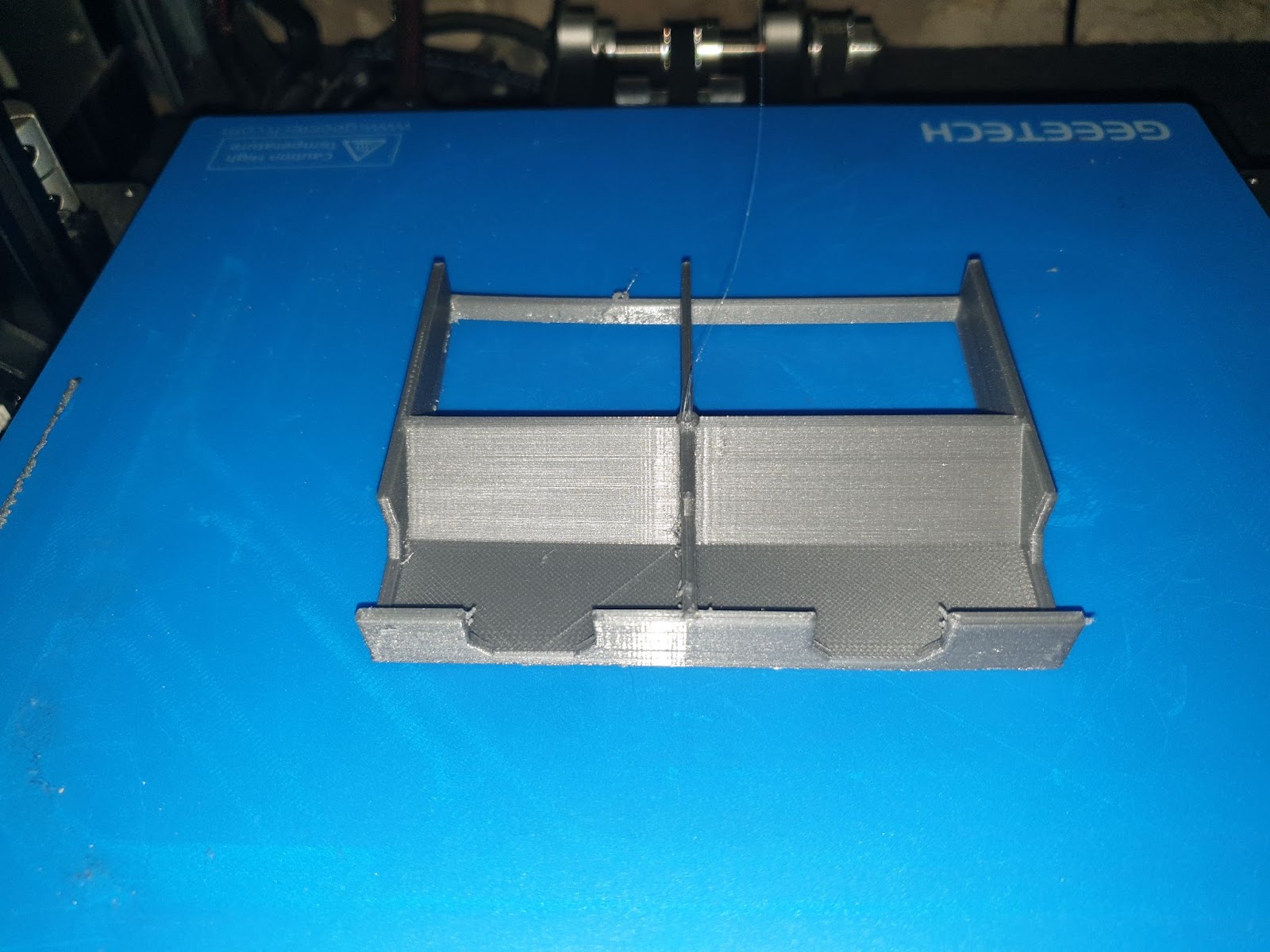

for my first test, I'm going to print something useful: a tray for AA and AAA batteries

https://www.printables.com/model/828-battery-holder

Well, I stopped printing as soon as I saw that: warping!

To remedy this, I added a 5mm brim. Afterwards everything went well!

You will notice in passing that there is quite a bit of stringing!

I am therefore going to modify some parameters in the slicer and in particular those linked to movement (“avoid crossing perimeter” for those who want the technical details!)

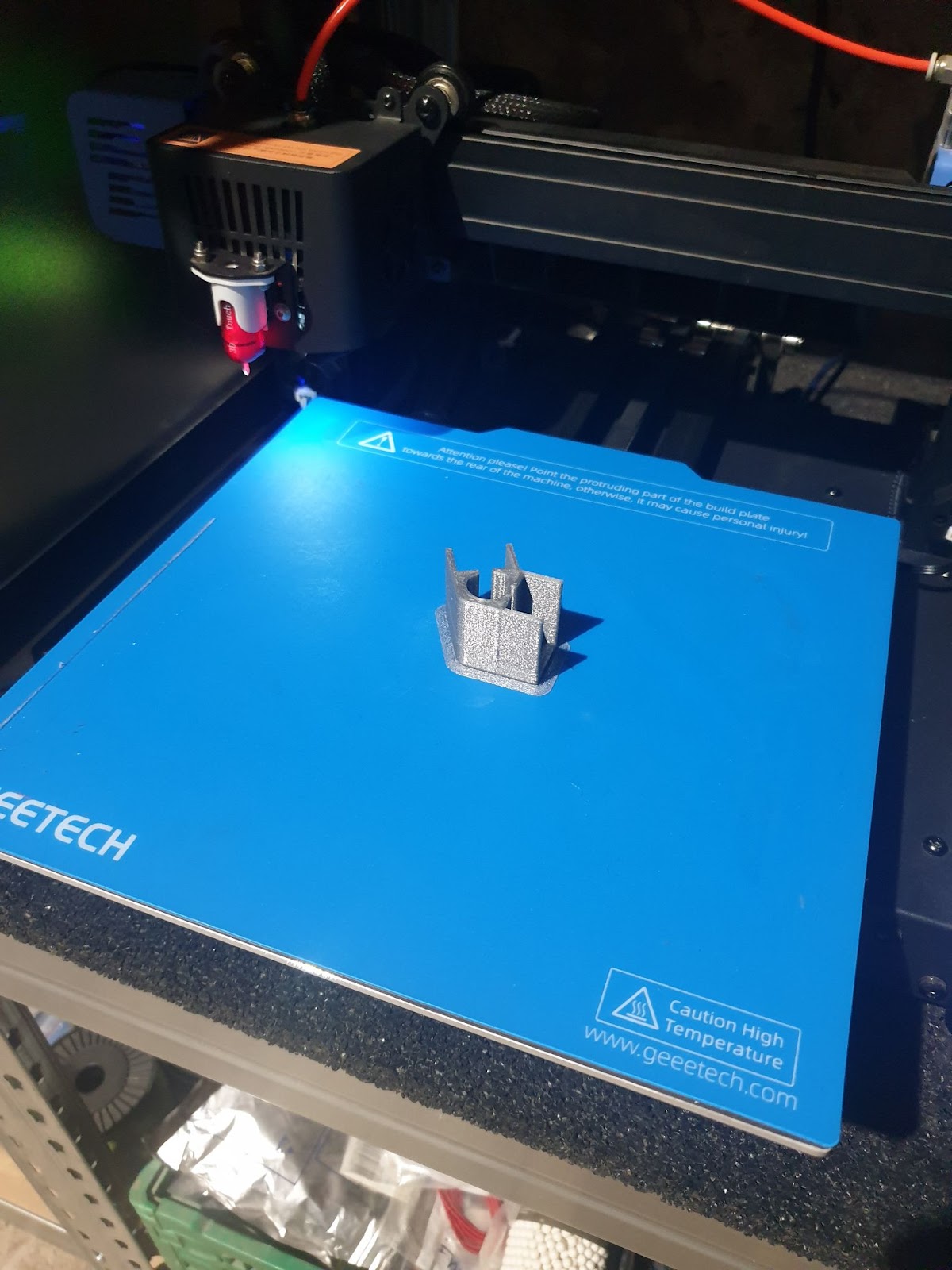

For my second test, I'm going with more technical pieces: I'm going to make a hexagonal shelf for my daughter.

https://www.printables.com/model/57664

This time, with the modifications, it's much cleaner!

So here we go for mass production!!!!! 😁

And the result:

Finally for my last test, I am going to make a Japanese style lamp:

https://www.printables.com/model/433807-japanese-lamp-pagode-light

I change machine in passing and switch to the mizar-s because the thunder has a clogging problem and requires in-depth maintenance.

Here is the result :

Conclusion :

This is the first time I've tested silver-colored PETG. Already for the color, it's really nice! It’s a change from the usual colors of PETG.

Then, like all PETG (the good ones), in terms of technical characteristics, it's there: the shelf is still on the wall and complete, I reassure you.

Regarding printing, unfortunately you have to be careful to respect the speed and heating recommendations. So we are not on a fast PETG. Finally, like all PETG, it tends to bleed, due to the fluidity characteristic, but this one still tends to have less stringing than others I have had. Indeed, the mizar-s which made the lamp and which has a lower movement speed than the thunder did not generate more stringing.

Available at around €20 per kilo, in my opinion it is a good PETG for the price. In any case I am satisfied with it.

Thanks to Aceaddity and Nozzler for allowing me to test this filament.